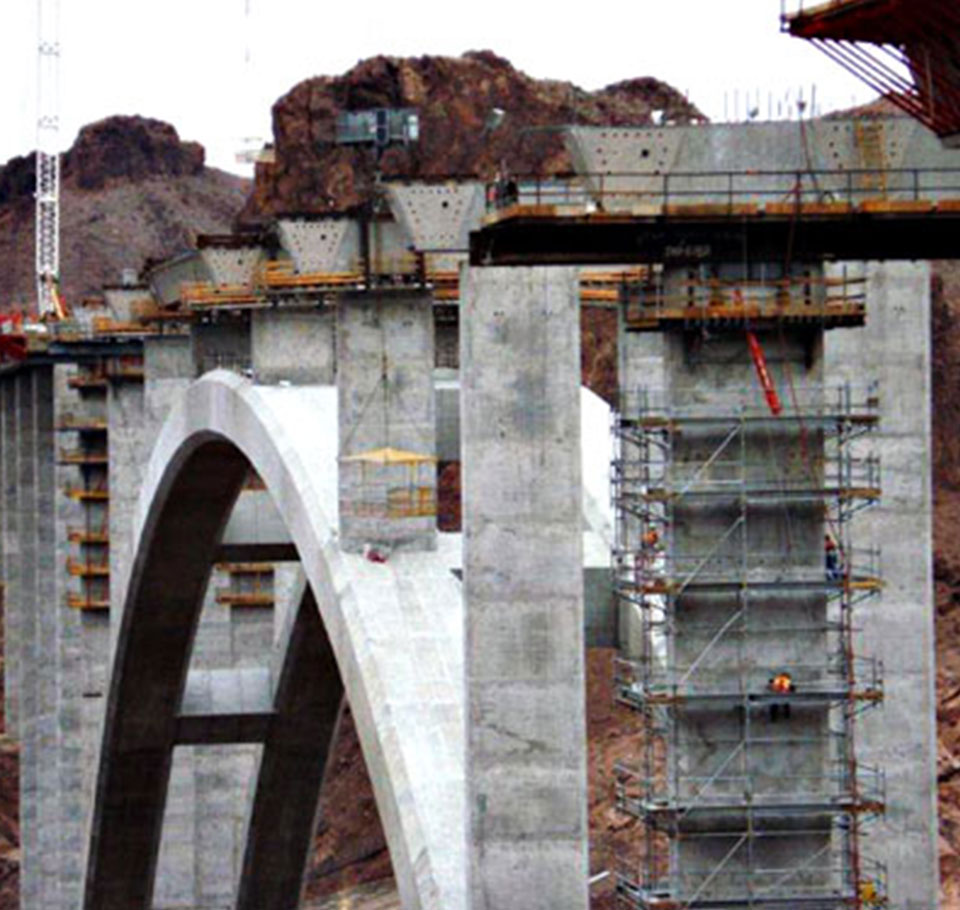

Hoover Dam Bypass

During construction of the Hoover Dam Bypass the Truesdell Corporation was consulted to repair some ‘hairline’ issues that were becoming quite visible. Small cracks had developed in the arch during construction.

Truesdell Corporation proposed a method of epoxy adhesive injection which would permanently rebonding the concrete hat had cracked, split or delaminated. Utilizing state of the art, highly sophisticated injection equipment with two metering pumps allows us to repair cracks as small as .002 inches wide and fill cracks to a depth of 20 feet or more.

To achieve full-depth penetration, the operator injects the adhesive into a port until it begins to show at an adjacent port. The first port is then plugged and injection is resumed at the adjacent port. This procedure continues until all cracks or voids are filled. Depending on the importance of aesthetics, special finishing techniques may be employed to render an acceptable architectural finish.

Once the bridge deck was placed, Truesdell Corporation sealed the concrete bridge deck with methacrylate. Methacrylate is a ‘healer-sealer’ which is designed to help seal out moisture from penetrating the bridge deck. Work consists of cleaning the concrete surface often with abrasion blasting (shotblast) and compressed air. Material is applied liberally and spread with brooms and/or squeegees to flood the entire surface and seal all visible cracks. Before the surface dried a skid/slip resistance surface was achieved by broadcasting sand into the material.